stronghold builder’s guide

Minecraft’s strongholds are vast‚ underground structures brimming with challenges and rewards‚ demanding a comprehensive guide for effective exploration and survival.

These complex labyrinths house the coveted End Portals‚ essential for progressing to the game’s final dimension and confronting the Ender Dragon.

Understanding stronghold layouts‚ navigating treacherous corridors‚ and preparing for unique encounters are crucial skills for any aspiring adventurer.

This tutorial will equip you with the knowledge to locate‚ conquer‚ and ultimately utilize these formidable structures to your advantage.

Mastering stronghold exploration unlocks access to rare loot‚ enchanted books‚ and the ultimate test of your Minecraft prowess.

What is a Stronghold?

Strongholds are naturally generated‚ expansive underground structures found in Minecraft worlds‚ representing a significant late-game challenge and reward. Unlike typical caves or mineshafts‚ strongholds aren’t simply excavated spaces; they are pre-built complexes constructed by an unknown civilization‚ hinting at a rich‚ albeit mysterious‚ history within the game’s lore.

These structures are characterized by their labyrinthine layout‚ featuring long‚ winding corridors‚ libraries filled with bookshelves‚ prison cells‚ and‚ most importantly‚ the End Portal room. The End Portal room is the sole location where players can activate a portal to The End dimension‚ initiating the final boss battle against the Ender Dragon.

Strongholds are unique in that they don’t generate consistently based on coordinates; instead‚ they are found using Eyes of Ender‚ items crafted from Blaze Powder and Ender Pearls. Each world contains a single stronghold‚ though its location can vary significantly between seeds. They are often found deep underground‚ typically below Y-level 30‚ adding to the difficulty of locating and accessing them. The structures are built from stone brick‚ mossy stone brick‚ and other sturdy materials‚ indicating a durable and ancient construction.

Why are Strongholds Important?

Strongholds hold paramount importance in Minecraft as they are the gateway to the End dimension and the final boss‚ the Ender Dragon. Without locating and activating the End Portal within a stronghold‚ players cannot progress to the game’s ultimate challenge and achieve full completion.

Beyond access to The End‚ strongholds are valuable sources of rare loot. Libraries within strongholds contain numerous bookshelves‚ offering a substantial supply of enchanted books‚ crucial for enhancing armor‚ weapons‚ and tools. Prison cells and other rooms often harbor valuable items like diamonds‚ gold‚ and other resources.

Furthermore‚ strongholds present a unique exploration experience‚ testing players’ navigational skills and combat prowess against silverfish‚ the stronghold’s resident hostile mob. Successfully navigating a stronghold demonstrates mastery of the game’s mechanics and provides a sense of accomplishment. They represent a significant milestone in a player’s Minecraft journey‚ marking the transition from survival to endgame content.

Locating a Stronghold

Finding a stronghold requires utilizing Eyes of Ender‚ crafted from Blaze Powder and Ender Pearls‚ to track down these hidden underground structures effectively.

These items guide players towards the stronghold’s approximate location‚ demanding patience and careful observation of their flight patterns.

Using Eyes of Ender

Eyes of Ender are paramount for locating strongholds‚ serving as your primary navigational tool in the vast Minecraft world. Crafting them requires combining Blaze Powder‚ obtained from Blazes in the Nether‚ with Ender Pearls‚ dropped by Endermen. Once crafted‚ right-clicking with an Eye of Ender equipped will cause it to float upwards‚ indicating the general direction of the nearest stronghold.

The Eye will travel a considerable distance before falling‚ so observe its trajectory carefully. Continue traveling in that direction and repeat the process; the Eye will eventually begin to descend into the ground when you are directly above the stronghold. Be prepared to dig downwards at this point! Remember that Eyes of Ender have a chance to break upon use‚ so bring a stack to ensure a successful search. Utilizing multiple Eyes of Ender simultaneously can refine the pinpointing process‚ leading you directly to the stronghold’s entrance.

Understanding Eye of Ender Behavior

Eye of Ender behavior isn’t always straightforward; understanding its nuances is key to efficient stronghold hunting. The Eye doesn’t lead in a perfectly straight line‚ often exhibiting curves and detours due to the game’s world generation. It’s crucial to follow the general direction‚ not necessarily the exact path the Eye takes.

Furthermore‚ the Eye’s descent doesn’t guarantee immediate access. It indicates the stronghold is below‚ but could be significantly deep underground‚ requiring extensive digging. Occasionally‚ the Eye may lead to a false positive – a location near‚ but not directly above‚ the stronghold. Be prepared for some exploratory digging! The closer you get‚ the more frequently the Eye will descend‚ confirming you’re on the right track. Remember‚ breakage is common‚ so carry ample supplies.

Seed-Based Stronghold Finding

Leveraging a world’s seed offers a direct route to stronghold locations‚ bypassing the need for extensive Eye of Ender tracking. Several online tools and websites specialize in analyzing Minecraft seeds‚ revealing the precise coordinates of strongholds within that specific world. These tools utilize the seed’s data to calculate the stronghold’s position based on the game’s generation algorithms.

However‚ remember that strongholds can span considerable areas‚ so the provided coordinates pinpoint a general region‚ not necessarily the exact entrance. Utilizing these coordinates in conjunction with Eyes of Ender can significantly reduce search time. Be aware that seed-based finding removes the element of discovery‚ but provides a reliable method for players prioritizing efficiency and direct access.

Navigating the Stronghold

Minecraft strongholds present intricate‚ labyrinthine layouts‚ demanding careful exploration and mapping to avoid getting hopelessly lost within their depths.

Expect winding corridors‚ hidden rooms‚ and unexpected drops‚ requiring constant vigilance and a keen sense of direction.

Stronghold Layout and Common Features

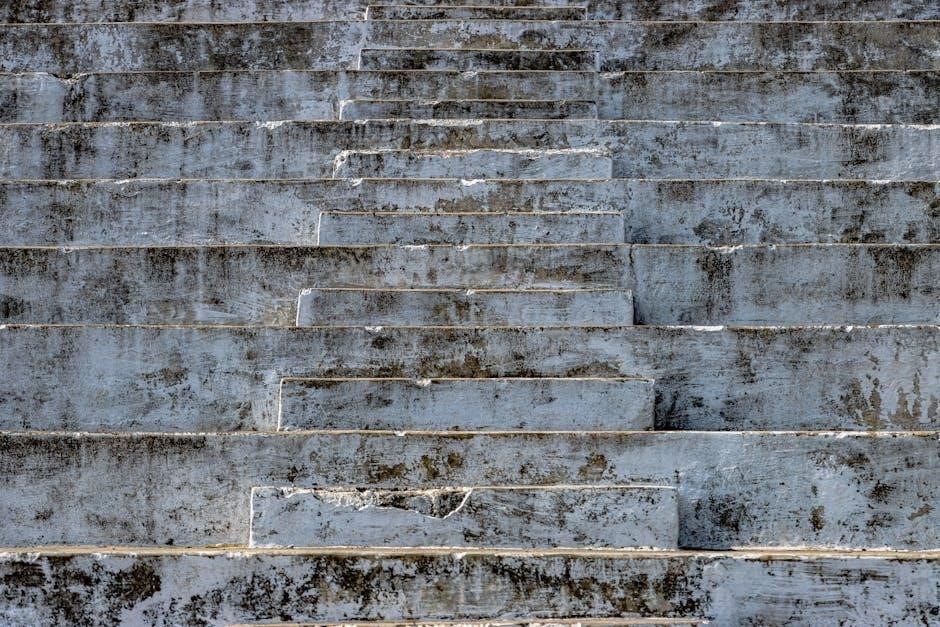

Minecraft strongholds don’t follow a rigid blueprint‚ but exhibit recurring architectural elements. Expect a sprawling network of stone brick corridors‚ often intersecting at odd angles‚ creating a disorienting maze for explorers.

Libraries are frequent occurrences‚ stacked high with bookshelves – a prime source for enchanted books. Prison cells‚ though often empty‚ can contain valuable loot hidden within chests. Spiral staircases descend into deeper sections‚ leading to more challenging areas.

You’ll encounter large‚ open rooms‚ sometimes containing flooded passages or lava pools‚ demanding caution. Stone brick walls are common‚ interspersed with mossy stone brick‚ indicating older sections. Pay attention to the presence of silverfish spawners‚ often concealed within stone brick‚ as these creatures can quickly overwhelm unprepared adventurers.

Strongholds frequently feature interconnected sections‚ with some areas looping back on themselves‚ making mapping essential. The overall structure feels ancient and deliberately complex‚ designed to protect the End Portal at its heart.

Dealing with Silverfish

Minecraft strongholds are notorious for their silverfish infestations‚ small but irritating mobs that can quickly become a serious threat. These creatures spawn from infested stone brick‚ appearing unexpectedly and swarming players. A swift response is crucial to avoid being overwhelmed.

Bringing a good sword‚ ideally enchanted with Knockback‚ is essential for dispatching them efficiently; Fire resistance potions are highly recommended‚ as silverfish are vulnerable to fire damage. Be prepared to break infested blocks quickly to prevent further spawns; a fortune pickaxe isn’t necessary‚ just speed.

Listen carefully for their distinctive hissing sound‚ which indicates a nearby spawner. Thoroughly explore each room‚ checking walls and ceilings for infested blocks. Consider bringing a water bucket to create temporary barriers or wash away groups of silverfish.

Don’t underestimate their numbers; even a small group can inflict significant damage. Prioritize eliminating spawners to control the infestation and ensure a safer exploration experience.

Mapping the Stronghold

Minecraft strongholds are complex‚ sprawling structures‚ making accurate mapping absolutely vital for efficient navigation and preventing endless wandering. Simply relying on memory is a recipe for getting hopelessly lost within their labyrinthine corridors.

Bring plenty of torches to illuminate your path and mark areas you’ve already explored. A map is essential‚ and consider using multiple maps to cover larger sections of the stronghold. Regularly place markers at key intersections and notable features like libraries or prison cells.

Coordinate systems‚ while advanced‚ can be incredibly helpful for larger strongholds‚ allowing you to precisely record locations. Don’t forget to map verticality – strongholds often have multiple levels connected by staircases and ladders.

Sketching a rough map on paper can also be beneficial‚ especially for visualizing the overall layout and identifying potential connections between different areas.

The End Portal Room

The End Portal Room is the stronghold’s ultimate goal‚ featuring a silverfish spawner and the iconic End Portal Frame awaiting activation with Eyes of Ender.

Carefully clear the room of silverfish before attempting to place the Eyes‚ and prepare for the journey to the End dimension!

Identifying the End Portal Frame

The End Portal Frame is a distinct structure within the End Portal Room‚ easily recognizable by its green‚ glowing blocks arranged in a rectangular shape. This frame isn’t complete upon discovery; it requires twelve Eyes of Ender to be inserted into each socket to activate the portal.

Each socket is designed to hold a single Eye of Ender‚ and the placement order doesn’t matter. However‚ finding enough Eyes of Ender can be a significant undertaking‚ requiring defeating Endermen to obtain Ender Pearls and combining them with Blaze Powder crafted from Blaze Rods found in the Nether.

Visually inspect the frame for any pre-placed Eyes‚ as some strongholds may have a few already inserted‚ reducing the number you need to craft. Be cautious when approaching‚ as silverfish often spawn nearby and can quickly overwhelm unprepared players. Successfully identifying and preparing the frame is the crucial first step towards reaching the End dimension.

Activating the End Portal

Once all twelve Eyes of Ender are correctly placed within the End Portal Frame‚ a swirling‚ black portal will materialize‚ signifying its activation. This portal serves as a one-way gateway to the End dimension‚ the final frontier of Minecraft.

Be absolutely certain you are fully prepared before entering‚ as the End is a challenging realm populated by the Ender Dragon and numerous Endermen. Consider bringing strong armor‚ potent weapons‚ healing potions‚ and blocks for building bridges across the void.

The activation process is irreversible without breaking the Eyes of Ender and replacing them‚ so double-check your inventory and readiness. Upon entering the portal‚ you’ll be transported to the End’s main island‚ initiating the final battle against the Ender Dragon.

Preparing for the End

Before venturing through the activated End Portal‚ meticulous preparation is paramount for survival. The End dimension presents unique challenges‚ demanding a robust inventory and strategic mindset. Prioritize diamond or netherite armor‚ fully enchanted for maximum protection against the Ender Dragon’s attacks and Endermen aggression.

A powerful weapon‚ such as a diamond or netherite sword with enchantments like Sharpness and Fire Aspect‚ is essential. Bring a bow with Power and Infinity enchantments‚ alongside a plentiful supply of arrows. Healing potions‚ golden apples‚ and enchanted golden apples are vital for restoring health during combat;

Consider bringing blocks – dirt‚ cobblestone‚ or end stone – to create bridges across the void and reach the obsidian towers surrounding the main island. A pumpkin to avoid Endermen eye contact and a water bucket for safe descents can also prove invaluable.

Stronghold Loot and Resources

Strongholds offer valuable rewards‚ including libraries filled with enchanted books‚ prison cells containing loot‚ and hidden depths harboring rare resources for dedicated explorers.

Discovering these treasures requires careful searching and a willingness to delve into the stronghold’s intricate network of corridors.

Libraries and Enchanted Books

Stronghold libraries are a haven for players seeking to enhance their gear with powerful enchantments. These rooms are densely packed with bookshelves‚ and more importantly‚ enchanted books. Finding these books is often a matter of luck‚ but the potential rewards are substantial.

Enchantments can drastically improve the effectiveness of weapons‚ armor‚ and tools‚ offering advantages in combat‚ resource gathering‚ and overall survival; Common enchantments found within stronghold libraries include Protection‚ Sharpness‚ Efficiency‚ and Fortune. Rarer enchantments‚ like Mending‚ can also appear‚ providing the ability to repair items using experience orbs.

Carefully examine each book to determine its enchantment before combining it with your desired item using an enchanting table. Remember that some enchantments are incompatible‚ so strategic planning is essential. Libraries represent a significant opportunity to acquire the enchantments needed to overcome the challenges that lie ahead‚ particularly the battle against the Ender Dragon.

Prison Cells and Valuable Items

Strongholds often contain prison cell areas‚ typically consisting of small‚ stone-walled rooms with iron bars. While seemingly desolate‚ these cells frequently harbor hidden treasures and valuable resources for the discerning explorer. Don’t dismiss these areas as empty; thorough searching is key.

Within these cells‚ players can discover chests containing items such as gold‚ iron‚ diamonds‚ and occasionally‚ rare artifacts. Saddles‚ music discs‚ and name tags are also common finds‚ offering utility and customization options. Be cautious‚ as some cells may be trapped or contain lurking silverfish‚ posing a threat to unprepared adventurers.

Pay close attention to the walls and floors of the prison cells‚ as secret passages or hidden compartments may exist. Breaking suspicious blocks can reveal additional loot or access to previously inaccessible areas. These cells represent a rewarding‚ albeit potentially dangerous‚ diversion within the larger stronghold complex.

Exploring the Stronghold’s Depths

Strongholds extend far beneath the surface‚ presenting a complex network of corridors‚ rooms‚ and hidden passages. Careful exploration is paramount‚ as the layout is rarely straightforward and can be incredibly disorienting. Bring plenty of torches to illuminate the darkness and prevent unwanted encounters.

Venture beyond the initial‚ more obvious chambers. Many valuable resources and secrets are concealed in the deeper‚ less-traveled sections of the stronghold. Be prepared to navigate tight spaces‚ climb staircases‚ and potentially encounter water-filled areas. Mapping your progress is highly recommended to avoid getting lost.

Listen for the telltale scratching sounds of silverfish‚ indicating their presence nearby. These creatures often infest the walls and ceilings‚ and can quickly overwhelm unprepared explorers. Proceed with caution and be ready to defend yourself; The depths hold the greatest rewards‚ but also the greatest risks.

Advanced Stronghold Techniques

Mastering stronghold exploration involves exploiting glitches‚ utilizing modded gear‚ and understanding advanced navigation tactics for optimal efficiency and resource acquisition.

Experienced players leverage these methods to overcome challenges and maximize their stronghold experience.

Stronghold Glitches and Exploits

Historically‚ Minecraft strongholds have been subject to various glitches and exploits that savvy players utilize to gain advantages. While many are patched with updates‚ awareness remains valuable. One common tactic involves exploiting the stronghold’s generation to clip through walls‚ allowing access to otherwise unreachable areas – though this can be unreliable.

Another‚ older exploit involved manipulating item frames to duplicate items within the stronghold’s libraries‚ though this is largely defunct. Speedrunning communities often document and utilize glitches to quickly navigate strongholds and reach the End Portal. It’s important to note that using exploits can sometimes corrupt world data‚ so backups are strongly recommended.

Furthermore‚ understanding how the game generates strongholds can allow players to predict potential layouts and locate key features more efficiently. While not a glitch‚ this knowledge is a powerful tool. Always exercise caution when attempting exploits‚ as they may alter the intended gameplay experience and potentially damage your world.

Utilizing Modded Gear in Strongholds

For players embracing Minecraft mods‚ strongholds present unique opportunities to leverage enhanced gear. Mods offering improved mining speed drastically reduce the time spent navigating the labyrinthine corridors. Those with enhanced vision or night vision capabilities are invaluable for exploring dimly lit areas‚ minimizing encounters with silverfish.

Combat-focused mods‚ providing powerful weapons and armor‚ significantly ease the challenge of dealing with silverfish swarms and potential hostile mobs spawned within. Inventory management mods are crucial for efficiently carrying the abundant resources found in stronghold libraries and prison cells.

Furthermore‚ mods offering advanced mapping tools can greatly simplify stronghold navigation‚ creating detailed layouts and marking points of interest. Remember to check mod compatibility and potential conflicts before entering a stronghold. Utilizing modded gear transforms the stronghold experience‚ making it both safer and more rewarding.